The Shaving Cadre

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shawn's forging shed

- Thread starter ShawnF

- Start date

Those are some sweet knives!

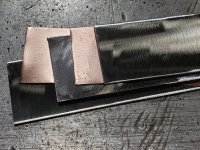

Got a bunch of new additions to the shop now. Finally made it to my first blacksmithing expo and came home with a four and a half pound drop of 80crv2 possibly for a hatchet request I got. Also picked up a hammer eye punch and a couple more pairs of blade tongs.

These are offset for holding longer pieces.

While there I got to see a forge welding demo and a grinding demo. Got my damascus blade evaluated by a knifemaker that works with Ben Abbot from forged in fire and the only issues he had with it were the cold shuts I already knew I had. All of my grinds looked good though.

I also found out that I REALLY need a 27 ton Big Blu forging press...... The one they were using there is just awesome.

Stopped at a co-workers house Thurs. after work to pick up this "little" beast...

My bench top drill press was pretty pathetic. I could grab the chuck and stop it.... Not squeal the belts, but actually stall the motor. I wouldn't recommend trying that with this one. Darn thing is all cast iron and weighs about 200 pounds. And my hand crank blower on my coal forge is Buffalo Forge Co. and they were made 2 hours away from me, so that was kind of cool.

While I was there he showed me his anvil he was thinking of selling. He only uses it to straighten things occasionally and thought if I wanted it he'd just replace it with a smaller one later for flattening. So I offered him my little one as a partial trade and came home with a new (to me) anvil also.

Went from my little 110 pound cast iron anvil with about 50% rebound to a 160 pound anvil with about 90% rebound. Has a nice but not annoying ring to it and I was able to forge out a knife blank much much faster than I could have with the little one.

The Vulcan has definitely been a good little anvil, but this one is just going to be so much more efficient.

These are offset for holding longer pieces.

While there I got to see a forge welding demo and a grinding demo. Got my damascus blade evaluated by a knifemaker that works with Ben Abbot from forged in fire and the only issues he had with it were the cold shuts I already knew I had. All of my grinds looked good though.

I also found out that I REALLY need a 27 ton Big Blu forging press...... The one they were using there is just awesome.

Stopped at a co-workers house Thurs. after work to pick up this "little" beast...

My bench top drill press was pretty pathetic. I could grab the chuck and stop it.... Not squeal the belts, but actually stall the motor. I wouldn't recommend trying that with this one. Darn thing is all cast iron and weighs about 200 pounds. And my hand crank blower on my coal forge is Buffalo Forge Co. and they were made 2 hours away from me, so that was kind of cool.

While I was there he showed me his anvil he was thinking of selling. He only uses it to straighten things occasionally and thought if I wanted it he'd just replace it with a smaller one later for flattening. So I offered him my little one as a partial trade and came home with a new (to me) anvil also.

Went from my little 110 pound cast iron anvil with about 50% rebound to a 160 pound anvil with about 90% rebound. Has a nice but not annoying ring to it and I was able to forge out a knife blank much much faster than I could have with the little one.

The Vulcan has definitely been a good little anvil, but this one is just going to be so much more efficient.

Some great finds and awesome "deals" Shawn! Did I read that you are making a hatchet? Super interested in seeing how that turns out!

NIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIICE!

I can pull out my AIA book and see if we can figure out a date. We are both Trenton buds now!  My main anvil is a Trenton.

My main anvil is a Trenton.

Great Pics Shawn!

Also, I'll be in PA the beginning of July. Can't guarantee I'll make it to your neck of the woods, but I'll try!

Also, I'll be in PA the beginning of July. Can't guarantee I'll make it to your neck of the woods, but I'll try!

Let me know. Maybe we can meet somewhere again if nothing else.Great Pics Shawn!

Also, I'll be in PA the beginning of July. Can't guarantee I'll make it to your neck of the woods, but I'll try!

Omg yes he has... He doesn't stop now. He won't be two until the middle of August but he is already in the terrible twos..... Hopefully he gets out of them early too....Wow the little guy has gotten big!

I know I have posted before about my dislike of using a piece of rail standing normally to make an anvil. I have said it is better to stand it on end to get more mass under the hammer. I have recently learned that that is not always correct. Armed with that new knowledge, I made this the other day.

It's a little rough since I only had about 20 minutes to cut it out and grind on it, but I am happy to say that it has passed the new test and has been approved for use.

In case you are wondering, the new information I learned is that when you are out working with grandpa, the ring is way more important than the mass.

I also had a few more tools that it was decided were a better fit with the new anvil.

I got it rubbed down with some linseed oil today to keep it from rusting. I think we have some 10 inch reject blocks at work, so I can cut one to length and get it mounted properly.

It's a little rough since I only had about 20 minutes to cut it out and grind on it, but I am happy to say that it has passed the new test and has been approved for use.

In case you are wondering, the new information I learned is that when you are out working with grandpa, the ring is way more important than the mass.

I also had a few more tools that it was decided were a better fit with the new anvil.

I got it rubbed down with some linseed oil today to keep it from rusting. I think we have some 10 inch reject blocks at work, so I can cut one to length and get it mounted properly.

Perfect use for a rail road track anvil!

Your anvil is looking good! Nice and oiled up too so it won't become a piece of rust out in the forge. Something tells me he will be your power hammer someday when swingling sledge hammers will sound like fun while gramps will be happy for the extra helper.

Your anvil is looking good! Nice and oiled up too so it won't become a piece of rust out in the forge. Something tells me he will be your power hammer someday when swingling sledge hammers will sound like fun while gramps will be happy for the extra helper.