The Shaving Cadre

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shawn's forging shed

- Thread starter ShawnF

- Start date

Shawn that is looking so sweet!

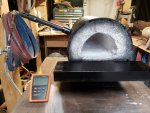

Reflective lining is in and curing, burner port is welded in place, and a coat of black paint.

View attachment 5779

about forearm size should be good. Hogs do a good job too though.So.... in the event I should accidentally murder someone, how big of chunks do I need to cut them up into? Just for information sake..

Dave in KY

Shave Newbie

That's true. Guy did that down here 30 years ago but got caughtabout forearm size should be good. Hogs do a good job too though.

Dave in KY

Shave Newbie

..... I should have added that he got off too as there was no evidence left.......That's true. Guy did that down here 30 years ago but got caught

And they are tasty too! The hogs...not the forearms. Though, in some cultures...humans are called long-pigs!about forearm size should be good. Hogs do a good job too though.

Did a little trial today. Took 3 files and stacked them on top of each other, tack welded them together, and stuck them in the forge.

Got that forge weld set then folded the billet in half and forge welded again. Then I twisted the billet and flattened it down some.

I cooled it in water which made my grain grow so that was a bad thing, but I cut half way through the billet and hammered it the rest of the way and my forge weld held.

Took the billet to the anvil with an 8 pound sledge hammer to the side of it so hard it started breaking the edges and the only separation is at the twist where it wasnt flattened all the way.

So overall I made a pretty successful forge weld.

Got that forge weld set then folded the billet in half and forge welded again. Then I twisted the billet and flattened it down some.

I cooled it in water which made my grain grow so that was a bad thing, but I cut half way through the billet and hammered it the rest of the way and my forge weld held.

Took the billet to the anvil with an 8 pound sledge hammer to the side of it so hard it started breaking the edges and the only separation is at the twist where it wasnt flattened all the way.

So overall I made a pretty successful forge weld.

woodpusher

TSC’s International Man of Meh

Did a little trial today. Took 3 files and stacked them on top of each other, tack welded them together, and stuck them in the forge.

Got that forge weld set then folded the billet in half and forge welded again. Then I twisted the billet and flattened it down some.

I cooled it in water which made my grain grow so that was a bad thing, but I cut half way through the billet and hammered it the rest of the way and my forge weld held.

Took the billet to the anvil with an 8 pound sledge hammer to the side of it so hard it started breaking the edges and the only separation is at the twist where it wasnt flattened all the way.

So overall I made a pretty successful forge weld.

I have absolutely no idea what you said...but I am pretty sure it was awesome! Glad to see the new forge working out for you!

He's speaking blacksmithese. You can only understand it all if you are holding a cross peen hammer in your hand  I got every work of it Shawn!

I got every work of it Shawn!

I keep making my son read your posts because HE thinks he can forge weld all sorts of random chunks of metal into the coolest things using his fire pit forge and my old broken hammer. I'm not sure what he thinks he is going to use as an anvil because we don't have one. Needless to say he has nothing on you.

Right now he is boiling his Dodge neon engine in a trash can full of drano, heated by his fire pit forge. I told him a REAL man would make soap with the the peanut oil I used to fry last year's turkey with the trash can drano when he's done boiling the engine. The kid just can't leave well enough alone. He says he's rebuilding the engine, i think he just wants an excuse to have another fire in the back yard.

@CBLindsay If he really wants to start forging Chris, he can get started for little to no money. A hole in the ground or a wooden box filled with dirt and a bit of a pit hollowed out is all he would need for a forge. A piece of pipe coming into the side of the pit to hook an old hair dryer onto makes a servicable blower. Charcoal is cheap fuel, yet burns hot and clean. A 1 to 2 pound yardsale ball peen hammer. (or both) And an 8 or 10 pound sledgehammer head in a stump or log piece for an anvil.

Hollow out a bit of a hole in the log end to stick the hammer head in keeping one face up, fill the pit with charcoal and light it, mound it up over the coals and turn the hair dryer on, stick the end of the steel into the hot core of the charcoal pile, pull it out when orange and beat it with the ball peen.

Same thing I did when I made GearNoir's knife for the exchange, only I used coal in a metal pot with a hand crank blower, and a small anvil instead of a hammer head.

As far as a complaint that the hammer head would be too small for an anvil, you are only going to move as much area as your swung hammer head will cover. As long as you have that much, you are good. Charlie Lewis makes amazing razors on a post anvil. A piece of 3 inch diameter solid round stock stood on end.

You really can do a lot with very little in this hobby.

Hollow out a bit of a hole in the log end to stick the hammer head in keeping one face up, fill the pit with charcoal and light it, mound it up over the coals and turn the hair dryer on, stick the end of the steel into the hot core of the charcoal pile, pull it out when orange and beat it with the ball peen.

Same thing I did when I made GearNoir's knife for the exchange, only I used coal in a metal pot with a hand crank blower, and a small anvil instead of a hammer head.

As far as a complaint that the hammer head would be too small for an anvil, you are only going to move as much area as your swung hammer head will cover. As long as you have that much, you are good. Charlie Lewis makes amazing razors on a post anvil. A piece of 3 inch diameter solid round stock stood on end.

You really can do a lot with very little in this hobby.

Reminds me of stories I heard working in the burn unitRight now he is boiling his Dodge neon engine in a trash can full of drano, heated by his fire pit forge. I told him a REAL man would make soap with the the peanut oil I used to fry last year's turkey with the trash can drano when he's done boiling the engine. The kid just can't leave well enough alone. He says he's rebuilding the engine, i think he just wants an excuse to have another fire in the back yard.