I've still got plenty of mental youth. Trouble is that the body won't keep up with it anymore.

The Shaving Cadre

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Words of wisd..... Yeah right.... We all know better than that!

- Thread starter ShawnF

- Start date

Dave in KY

Shave Newbie

Debatable but perhapsI probably feel older than he does though.....

Ain't that the truthI've still got plenty of mental youth. Trouble is that the body won't keep up with it anymore.

A fine pair of boots Shawn. Sounds like work is hopping and I'm plenty jealous of all the tearing apart and rebuilding that you get to do.

Grandpa? Guys our age don't seem that old yet, but I have boys in their 20's so I could be a a gramps by now too. Do I need to make you a cane like mine?

Grandpa? Guys our age don't seem that old yet, but I have boys in their 20's so I could be a a gramps by now too. Do I need to make you a cane like mine?

I hope my razors aren't adding to much to your busyness.

Actually I feel bad for taking so long with them, so if you aren't worried we are good buddy!I hope my razors aren't adding to much to your busyness.

I think I have a spare razor or two around here so no sweat here.Actually I feel bad for taking so long with them, so if you aren't worried we are good buddy!

Grandpa?! Holy Crap! I don't even have kids and you are working on another generation! I guess I have some catching up to do!

Really though...Congratulations! I am sure the new edition will get spoiled! And great kicks by the way...those boots look comfy!

Really though...Congratulations! I am sure the new edition will get spoiled! And great kicks by the way...those boots look comfy!

Man I have a lot to catch up on here. A few shaves to start.

Sorrentino brush, CBL dragons blood soap, and a Genco straight. This one didn't go well. The soap is awesome, but the edge on the Genco is in dire need of a touch-up. Pretty rough shave as I was too bullheaded/lazy to get another razor out.

Skipped a day and then went with a feather pro in my CJB. Soap was RR sandalwood. This is a discontinued formula and scent. The formula is on the better end for RR soaps, but nowhere near Lisa's or CBL level. The scent however is my favorite sandalwood scent. Quite possibly my favorite soap scent.

Shave went ok other than surgically removing a couple bumps caused by the previous shave.

This one was picked by the boss. Well, the soap and brush were. These are products that were purchased for her. She usually showers after me and while I am shaving, so if she is shaving her legs, she just uses what I have for lather, so I often let her pick the products. She still uses her cart though, but I used my Dandy Shave razor with a Nacet blade. The brush is a Whipped Dog with a Plissoft knot. I'm not a fan of the knot. Not a fan of synths overall, but this one feels like it stabs you. Just too springy making the tips poke you.

Last nights shave was a sample of Chambers cream. I've been wanting to try it out knowing where it is from, but I have to say that I'm not a fan of the way it performs for me. Not sure if it is a tallow product or not, but it performs like a non-tallow product for me. Very little glide or cushion while shaving. I do have to say that despite some mild irritation, my skin feels really good today. So there is some good stuff in there, just not a great performer for me personally.

Work has been busy. Went in Friday while the plant was shut down to work on the airlocks on the dust collection systems.

Here is a view of where I was working taken from the 25 foot high roof.

You can see the two cones on top of the silo. At the bottom of them is a round airlock. There are rotary fins in there that have rubber wipers to keep it air tight yet allow sawdust to fall into the silo. These wipers were worn so that means pulling off a 90 pound round steel plate, a drive sprocket, and two bearings just to get to the rotary. That weighs about 150 pounds on it's own. The new one had to be puled up onto the silo, and the old one sent down to be rebuilt while the new one was being installed. Installation was complicated by trying to force everything back together with the oversized rubber sweepers. Then we did the second one.

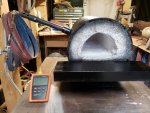

Home today and working on the forge. Got the refractory fired and cured. Then welded the burner port into place, welded a shelf on the front, and gave it the IR reflective coating, as well as a coat of paint.

Sorrentino brush, CBL dragons blood soap, and a Genco straight. This one didn't go well. The soap is awesome, but the edge on the Genco is in dire need of a touch-up. Pretty rough shave as I was too bullheaded/lazy to get another razor out.

Skipped a day and then went with a feather pro in my CJB. Soap was RR sandalwood. This is a discontinued formula and scent. The formula is on the better end for RR soaps, but nowhere near Lisa's or CBL level. The scent however is my favorite sandalwood scent. Quite possibly my favorite soap scent.

Shave went ok other than surgically removing a couple bumps caused by the previous shave.

This one was picked by the boss. Well, the soap and brush were. These are products that were purchased for her. She usually showers after me and while I am shaving, so if she is shaving her legs, she just uses what I have for lather, so I often let her pick the products. She still uses her cart though, but I used my Dandy Shave razor with a Nacet blade. The brush is a Whipped Dog with a Plissoft knot. I'm not a fan of the knot. Not a fan of synths overall, but this one feels like it stabs you. Just too springy making the tips poke you.

Last nights shave was a sample of Chambers cream. I've been wanting to try it out knowing where it is from, but I have to say that I'm not a fan of the way it performs for me. Not sure if it is a tallow product or not, but it performs like a non-tallow product for me. Very little glide or cushion while shaving. I do have to say that despite some mild irritation, my skin feels really good today. So there is some good stuff in there, just not a great performer for me personally.

Work has been busy. Went in Friday while the plant was shut down to work on the airlocks on the dust collection systems.

Here is a view of where I was working taken from the 25 foot high roof.

You can see the two cones on top of the silo. At the bottom of them is a round airlock. There are rotary fins in there that have rubber wipers to keep it air tight yet allow sawdust to fall into the silo. These wipers were worn so that means pulling off a 90 pound round steel plate, a drive sprocket, and two bearings just to get to the rotary. That weighs about 150 pounds on it's own. The new one had to be puled up onto the silo, and the old one sent down to be rebuilt while the new one was being installed. Installation was complicated by trying to force everything back together with the oversized rubber sweepers. Then we did the second one.

Home today and working on the forge. Got the refractory fired and cured. Then welded the burner port into place, welded a shelf on the front, and gave it the IR reflective coating, as well as a coat of paint.

Dave in KY

Shave Newbie

Nice shaves and cool work update Shawn. I prefer a fan knot but that Sorrentino brush is gorgeous !!

WOW! Now that is a hell of an update! Shaves are great and you look super busy at work! But the forge is looking awesome! Very interested to see what comes out of the forge!

"Forged in Fire" here we come!Home today and working on the forge. Got the refractory fired and cured. Then welded the burner port into place, welded a shelf on the front, and gave it the IR reflective coating, as well as a coat of paint.

SteveChuckFrank

Close Enough*

Great shaves Shawn! Love the pics from the rooftop at work. That’s pretty interesting stuff. The forge is coming along too! Like Don said, I can’t wait to see what you create with it!

Nice looking forge Shawn! I must say, your job always makes me long for my days when I ran a building and had all those interesting things to do. There's always something to get done.

Great shaves except that one.

Great shaves except that one.