OpusX

TSC’s Master of Warp Cores, Alchemy, Ale, & Cider

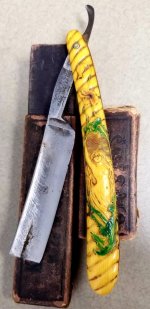

The straight razor bug has bit, and now I'm already getting into projects. I just picked up a K.W. & Co. razor locally, as overall I liked the look, specifally the scales. As I was looking at it during the meetup I noticed a pretty nasty chip in the blade. I thought to myself "ah...I can reprofile that edge all the way up to the chip and see if we can work from there". Granted I've not done such a thing on a razor, but I have a touch of experience with making edges from steel.

I wanted to work to document what I'm doing, as well as see what feedback and tips the cadre has at large for such a task.

My current plan:

The blade chip we're going to try and remove

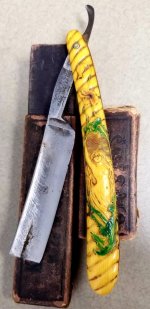

Also for the heck of it and reference, here is a fun dashi style knife I made from a water jet scrap (I think I made 3-4 of these) from the knife shop (when I did such things)

I wanted to work to document what I'm doing, as well as see what feedback and tips the cadre has at large for such a task.

My current plan:

- Glass the edge to take it down so I don't oopsy myself

- Get out the fine metal files and hand grind the blade edge perpendicular to the file until we have hit the chip depth

- I have concern that this is a dangerous step that may cause more chipping as that is some thin steel

- Tape up the spine and start a 500/1000/2000 wet sand profile on the edge

- Progress to burr method lapping paper progression

- Strop

- Shave

The blade chip we're going to try and remove

Also for the heck of it and reference, here is a fun dashi style knife I made from a water jet scrap (I think I made 3-4 of these) from the knife shop (when I did such things)