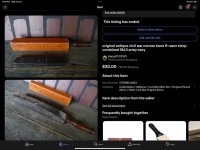

Antique Convex Razor Hone & Strop - Patented 1843

……………………………………………………………………………………………………………………………

Having become an early modern day hobby practitioner of razor sharpening techniques cataloged in a German grinders handbook in 1846 (Polytechnische Mitteilunge, volume 3), this hardware piece caught my eye. The German writer describes the use of multiple convexities in stone shapes with increasing fineness of grind as a “very advantageous practice described to be used only by knife makers, knife grinders, and barbers”.

It appears as if the inventor and patent holder of this device, one Wm. D. Boardman, and then a manufacturer, one F. J. Ordway were seeking to present a product that offered those particular European razor sharpening techniques in a singular mobile product.

The 1843 Patent - William D. Boardman

………………………………………………………………………………………………………………………………

Described is a paddle strop like device where adjustable flex steel plate is used to hone a razor in what I call the backbevel area behind the apex. Planning appears to use a paint like semi-solid coating and abrasive mixture, or to have a polished surface coated with an abrasive paste designed for that purpose.

Specific techniques and attached stropping materials are not described in the patent.

A William Dean Boardman from the area is recorded to have passed away in 1854 at the age of 49. My research has not yet uncovered inventor versions of the product or marketing efforts between 1843 and his death.

F. J. Ordway - The American Convex Hone and Razor Strop Combined Product

……………………………………………………………………………………………………………………………

My research has not revealed a F. J. Ordway in the area of fabrication. There is property listing the Ordway surname name in Cambridgeport, MA and references to the carpentry craft. The Boston area was known to be a key player in the Industrial Revolution and would be a likely area to seek the manufacture of a unique entrepreneurial offering.

This is the only known (by me) example of this product to survive the test of time. Given that it is remarkably well preserved and found in the State of Vermont, research lead me to a Franklin Ordway who was recorded to have passed away in 1865 at the age of 40. If this gentleman is indeed the hand who sought to manufacture and market this product, one could assume he may have traveled to relatives in Cambridgeport for fabrication and that family back at his home in VT may have hung on to this singular piece over the years for sentimental reasons.

The instructions for the piece read as follows:

Directions for Using.

First, lay the Strop Down upon the table , with No. 1 Hone up, and oil the Hone before using; then hold the Razor with both hands, as you would upon a grindstone, square with the Strop (or at right angles), carrying the Razor towards the edge, and not draw it back, giving it any lateral motion that the operator may see fit. If the razor has been honed up a straight hone heretofore, there is a blunt edge; this will have to be taken down to the convex of the Hone No. 1. When the edge is produced, then apply the Razor to paste No. 2, a few strokes; then to No. 3,—finishing upon No. 4. Use sweet oil upon the Hone, and wipe the hone after using it. Paste in the end of the Strop, but not needed for years.

N.B. (Nota bene, or note well) — ALWAYS STROP YOUR RAZOR AFTER SHAVING, AND YOU WILL HAVE NO DIFFICULTY IN SHAVING.

MY OBSERVATIONS, THOUGHTS AND COMMENTS

……………………………………………………………………………………………………………………………..

What an ingenious device seeming to allow users to easily implement the concept of a hollow razor bevel to their razors as cataloged in German writings. One has to admit, the title “The American” is just great marketing. Obviously the example does not offer the multiple curvatures that are part of the original patent but give a more stable honing surface than there might be in an adjustable and flexible piece.

The particular number for sides of the Hone and Strop are indicated upon the box. A jewelers like rouge abrasive still exists in the reservoir end.

Under magnification the Honing surface appears to be a composite coating with abrasive particles as the patent describes. On a flexible surface, I’d expect a cracking problem.

The stropping surfaces are very thin and thought to be leather. Since only one abrasive was included for strop application, it raises some question in my mind as to volume or variance as part of the original manufacture.

Before detractors of the use of a convex hones jump at this singular surviving example as proof of concept failure, we should consider the short life cycles of the time period, as well as things like the American Civil War impact and evolving hair removal technologies brought on by the Industrial Revolution.

If I was of the wealth and mindset to pursue fabrication of a current day tool of similar design it would be:

No 1. - similar shape, with slight cross crowning and cBN abrasive at 3-5k grit

No 2. - 50% reduction in length crowning, slight cross crowning, cBN abrasive at 1µ particle

No 3. - Replaceable ceramic or ultra fine durable synthetic with very slight crown at .5µ particle

No 4. - Replaceable mounted leather strop

Selling price $50, max………. A future?? Uh, I doubt it, but I am available for product testing for anyone of the entrepreneurial mindset to pursue it.

……………………………………………………………………………………………………………………………

Having become an early modern day hobby practitioner of razor sharpening techniques cataloged in a German grinders handbook in 1846 (Polytechnische Mitteilunge, volume 3), this hardware piece caught my eye. The German writer describes the use of multiple convexities in stone shapes with increasing fineness of grind as a “very advantageous practice described to be used only by knife makers, knife grinders, and barbers”.

It appears as if the inventor and patent holder of this device, one Wm. D. Boardman, and then a manufacturer, one F. J. Ordway were seeking to present a product that offered those particular European razor sharpening techniques in a singular mobile product.

The 1843 Patent - William D. Boardman

………………………………………………………………………………………………………………………………

Described is a paddle strop like device where adjustable flex steel plate is used to hone a razor in what I call the backbevel area behind the apex. Planning appears to use a paint like semi-solid coating and abrasive mixture, or to have a polished surface coated with an abrasive paste designed for that purpose.

Specific techniques and attached stropping materials are not described in the patent.

A William Dean Boardman from the area is recorded to have passed away in 1854 at the age of 49. My research has not yet uncovered inventor versions of the product or marketing efforts between 1843 and his death.

F. J. Ordway - The American Convex Hone and Razor Strop Combined Product

……………………………………………………………………………………………………………………………

My research has not revealed a F. J. Ordway in the area of fabrication. There is property listing the Ordway surname name in Cambridgeport, MA and references to the carpentry craft. The Boston area was known to be a key player in the Industrial Revolution and would be a likely area to seek the manufacture of a unique entrepreneurial offering.

This is the only known (by me) example of this product to survive the test of time. Given that it is remarkably well preserved and found in the State of Vermont, research lead me to a Franklin Ordway who was recorded to have passed away in 1865 at the age of 40. If this gentleman is indeed the hand who sought to manufacture and market this product, one could assume he may have traveled to relatives in Cambridgeport for fabrication and that family back at his home in VT may have hung on to this singular piece over the years for sentimental reasons.

The instructions for the piece read as follows:

Directions for Using.

First, lay the Strop Down upon the table , with No. 1 Hone up, and oil the Hone before using; then hold the Razor with both hands, as you would upon a grindstone, square with the Strop (or at right angles), carrying the Razor towards the edge, and not draw it back, giving it any lateral motion that the operator may see fit. If the razor has been honed up a straight hone heretofore, there is a blunt edge; this will have to be taken down to the convex of the Hone No. 1. When the edge is produced, then apply the Razor to paste No. 2, a few strokes; then to No. 3,—finishing upon No. 4. Use sweet oil upon the Hone, and wipe the hone after using it. Paste in the end of the Strop, but not needed for years.

N.B. (Nota bene, or note well) — ALWAYS STROP YOUR RAZOR AFTER SHAVING, AND YOU WILL HAVE NO DIFFICULTY IN SHAVING.

MY OBSERVATIONS, THOUGHTS AND COMMENTS

……………………………………………………………………………………………………………………………..

What an ingenious device seeming to allow users to easily implement the concept of a hollow razor bevel to their razors as cataloged in German writings. One has to admit, the title “The American” is just great marketing. Obviously the example does not offer the multiple curvatures that are part of the original patent but give a more stable honing surface than there might be in an adjustable and flexible piece.

The particular number for sides of the Hone and Strop are indicated upon the box. A jewelers like rouge abrasive still exists in the reservoir end.

Under magnification the Honing surface appears to be a composite coating with abrasive particles as the patent describes. On a flexible surface, I’d expect a cracking problem.

The stropping surfaces are very thin and thought to be leather. Since only one abrasive was included for strop application, it raises some question in my mind as to volume or variance as part of the original manufacture.

Before detractors of the use of a convex hones jump at this singular surviving example as proof of concept failure, we should consider the short life cycles of the time period, as well as things like the American Civil War impact and evolving hair removal technologies brought on by the Industrial Revolution.

If I was of the wealth and mindset to pursue fabrication of a current day tool of similar design it would be:

No 1. - similar shape, with slight cross crowning and cBN abrasive at 3-5k grit

No 2. - 50% reduction in length crowning, slight cross crowning, cBN abrasive at 1µ particle

No 3. - Replaceable ceramic or ultra fine durable synthetic with very slight crown at .5µ particle

No 4. - Replaceable mounted leather strop

Selling price $50, max………. A future?? Uh, I doubt it, but I am available for product testing for anyone of the entrepreneurial mindset to pursue it.